Pad & Screen Printing on Leather

Unique Assembly & Decorating offers the highest quality pad printing, screen printing, hot stamping, and industrial digital ink jet printing on leather (or leather like) parts.

Printing on Leather at Unique

While we can certainly hot stamp on leather and similar products, when asked to decorate leather or leatherette finished goods, we often recommend pad printing or screen printing over other more traditional options like hot stamping (embossing or debossing). The risk of damaging the leather or leather-like finished goods due to the heat and pressure required to hot stamp leather or leather-like goods if often too high. With the details of your project, Unique will recommend the best printing or decorating option for your project.

Leather Printing & Decorating Services

Do you need a logo or image on a leather product? Unique is capable of the following printing & decorating services for leather:

Pad Printing

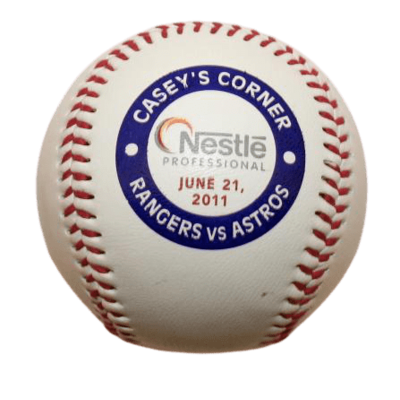

Pad printing is a printing method that allows the transfer of a 2-dimensional image onto a 3-dimensional object. While just as effective for flat surfaces, this process is most often used for printing on parts that are round, have complex curvature, that are round, have a concave or convex surface, or have recessed or raised areas.

Pad printing became popular following World War II when watchmakers began printing on the curved surfaces of watch faces. This ability to print on unprintable substrates has turned the pad printing process into a well-established technology and is used today across multiple industries such as medical, cosmetics, electronics, and more.

Screen Printing

Screen printing is a printing method that allows the transfer of large opaque images onto flat (or relatively flat) and cylindrical plastic, glass, and metal objects. The origins of screen printing date back thousands of years — from early Polynesian natives who forced die through cut-out patterns in banana leaves to decorate cloth, to cave walls found in France and Spain that were decorated by way of stencils and colorant applied with blowpipes, to the Japanese creating intricate designs during the Sung Dynasty (A.D 960-1280). Today, screen printing is used to decorate rigid parts for a variety of industries.

Hot Stamping

Hot stamping (or foil stamping) is a dry process that uses heat and pressure to transfer reflective metallic foil and high gloss opaque colored foil to the part. It is also the process used to decorate raised areas and is also known as tipping. In this process, the pigment or metallic foil is transferred to raised letters or a raised area of a plastic part.

Because hot stamping is a dry process (unlike screen printing or pad printing), decorated parts can easily be bulk packed on-line with fewer concerns about damage to the decorated image -- this can save on packaging and handling costs. Polypropylene and polyethylene parts can typically be hot stamped without pretreatment which provides cost savings over pad printing and screen printing.

Heat Transfer Decal

Hot stamping (or foil stamping) is a dry process that uses heat and pressure to transfer reflective metallic foil and high gloss opaque colored foil to the part. It is also the process used to decorate raised areas and is also known as tipping. In this process, the pigment or metallic foil is transferred to raised letters or a raised area of a plastic part.

Because hot stamping is a dry process (unlike screen printing or pad printing), decorated parts can easily be bulk packed on-line with fewer concerns about damage to the decorated image -- this can save on packaging and handling costs. Polypropylene and polyethylene parts can typically be hot stamped without pretreatment which provides cost savings over pad printing and screen printing.

Project Gallery

Unique Assembly is able to print or decorate nearly any rigid surface – flat or cylindrical, concave or convex, raised or recessed, and painted or coated surfaces.

Have Questions?

We have the capabilities to work with companies across the US and are excited to work with you on your upcoming project!

Contact Us (Phone & Fax)

630-241-4300Find Us

Unique Assembly & Decorating, Inc.

2550 Wisconsin Ave,

Downers Grove, IL 60515