Customized Product Decorating

By combining a variety of product decorating services with over 20 years of experience, we can offer the best rigid surface decorating services for each project, which in most cases is also the most economical.

Product Decorating Services

Since starting operations in 1993, it has been our goal to provide the highest quality custom product decorating services for every customer and every order. We are backed by an expertly trained staff, an ISO 9001:2015 quality management system and a top-down commitment to maintaining the highest quality hot stamping, foil banding, heat transfer decal decorating, and colorization & hologramming services. Unique is ready to take on your product decorating needs for nearly any part with a hard, rigid surface, including plastic, glass, metal, wood or ceramic surfaces.

Pad Printing Capabilities

We provide custom pad printing services throughout the United States and Canada. No matter where our customers are located, they have come to rely on our expert staff and our knowledge of the pad printing process.

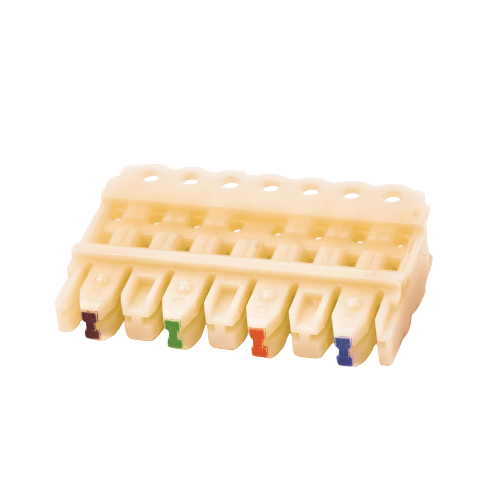

Our precision fixtures are designed to position each part accurately, ensuring exact imprint repeatability and tight registration for multicolor jobs. These tools range from cast and poured epoxy and urethane fixtures to CNC machined aluminum fixtures.

By using laser etching, with this laser plate maker, we can create pad printing plates directly from the digital file which eliminates the film required for the traditional method of making pad printing plates.

We have in-house color matching capabilities to specific PMS colors, and we can custom color match when provided color chips or swatches. With screen printing, we can typically match any PMS or custom color regardless of the part color in one-pass.

To achieve the best results, we require vector images for most of our printing and decorating processes - pad printing, screen printing, hot stamping, and laser engraving.

For pretreating polypropylene and polyethylene parts, we have the option of plasma treating. Plasma is a gas that has the capacity to conduct electricity.

Flame treating lowers the surface tension of the plastic to allow for proper ink adhesion. We have custom-built flame treating equipment for both flat parts such as polypropylene caps for CBD products and cylindrical polyethylene bottles for the health and beauty industry.

To achieve proper ink adhesion, the printing or decorating surface must be free of all surface contaminates. Common surface contaminates are dust, mold release, and hand oils from parts being handled without gloves.

For both plastic and metal parts, post-treatment is sometimes required to achieve maximum ink adhesion. And for glass parts, post-treatment is almost always required for maximum ink adhesion.

Printing & Decorating Solutions for all surface types

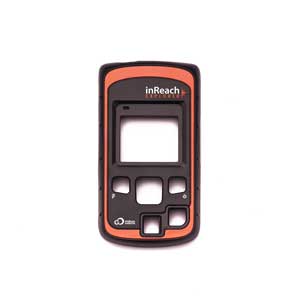

By having a full range of product printing and product decorating capabilities, Unique Assembly can print or decorate nearly any rigid surface – flat or cylindrical, concave or convex, raised or recessed, and painted or coated surfaces.

Have Questions?

We have the capabilities to work with companies across the US and are excited to work with you on your upcoming project!

Contact Us (Phone & Fax)

630-241-4300Find Us

Unique Assembly & Decorating, Inc.

2550 Wisconsin Ave,

Downers Grove, IL 60515